Whether you're welding in a high-volume fabrication shop or working on a custom project in the field, selecting the right welding wire is essential for achieving strong, clean, and reliable welds. The right choice depends on several factors—base material, thickness, welding process, position, and environmental conditions. In this article, we’ll walk you through the key considerations to help you make the best decision for your application.

The first—and most critical—step is identifying the type of metal you’re welding:

Carbon Steel: Most common and widely used. Choose a mild steel wire like ER70S-6 for solid wire MIG welding. It provides good deoxidizers and works well with rust or scale on the surface.

Stainless Steel: Use wires like ER308L, ER309, or ER316, depending on the stainless grade and service environment. These wires are corrosion-resistant and suitable for food-grade, petrochemical, or marine use.

Aluminum: Requires a different setup and filler wire, typically ER4043 or ER5356, depending on the alloy. Aluminum wire is softer and requires spool guns or push-pull systems for smooth feeding.

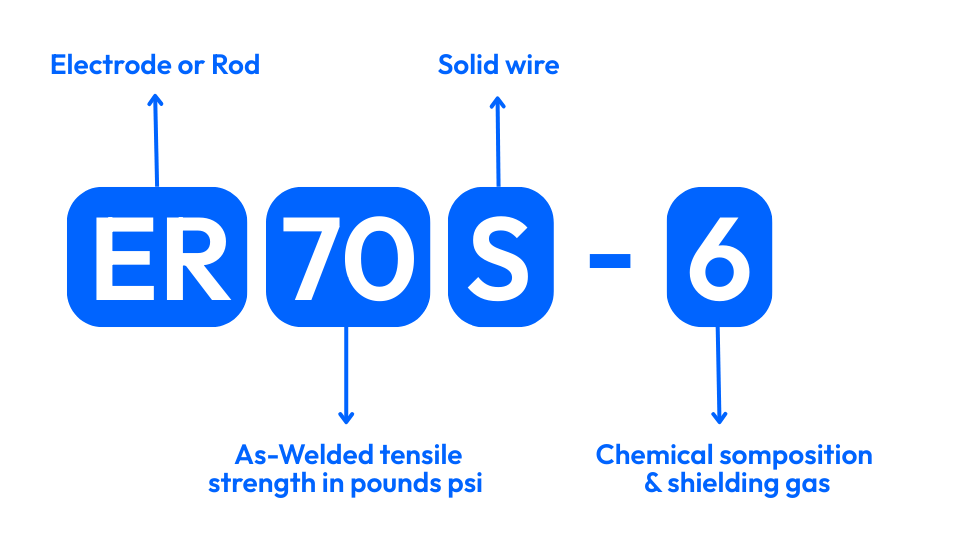

Tip: Matching the filler wire to your base metal's chemistry is crucial to prevent cracks and corrosion. Example of grades meaning can be seen below.

At CUMIC, we supply a comprehensive range of welding consumables compatible with various base materials, ensuring quality and reliability for your specific applications.

Wire diameter plays a significant role in weld penetration and bead appearance:

Thin Metals (Below 3mm): Use thinner wire (e.g. 0.6–0.8mm or 0.023–0.030 inch) for better control and reduced heat input.

Medium to Thick Metals (Above 3mm): Thicker wires (e.g. 0.9–1.2mm or 0.035–0.045 inch) provide deeper penetration and stronger welds.

Note: Thicker wires also require more amperage and higher voltage settings.

Different welding methods work best with specific wire types:

Flux-Cored Arc Welding (FCAW): Best for outdoor or heavy-duty welding. Choose self-shielded wire (no gas needed) for convenience or dual-shielded (with external gas) for deeper penetration.

MIG (GMAW): Use solid wire (e.g. ER70S-6) or flux-cored wire for structural jobs. MIG is fast and efficient, ideal for production settings.

TIG (GTAW): Typically uses cut-length filler rods rather than continuous wire. But wire selection is still important for material compatibility and weld quality.

Looking for specific grades or diameters of welding wire? Global clients trust CUMIC for consistent quality and on-time delivery. From shipbuilding, oil & gas pipeline to automotive and machinery, we've got the welding consumables to match. Contact cumic@cumic.com partner with us for your welding wire and rod needs—we’re ready to deliver.