Wear-resistant plate, also known as abrasion-resistant plate, is used in various industries and applications where abrasion, wear and tear requirements are particularly critical.However, while the wear plate is favored for characteristics such as high alloy additions and high hardness, if not properly processed, cracks may occur in the plate.

We feel your pain. In this article, we are going to discuss:

3 common types of cracking during processing: Cut-edge/weld/bending Cracking

Why do they happen?

Effective tips on how to avoid them

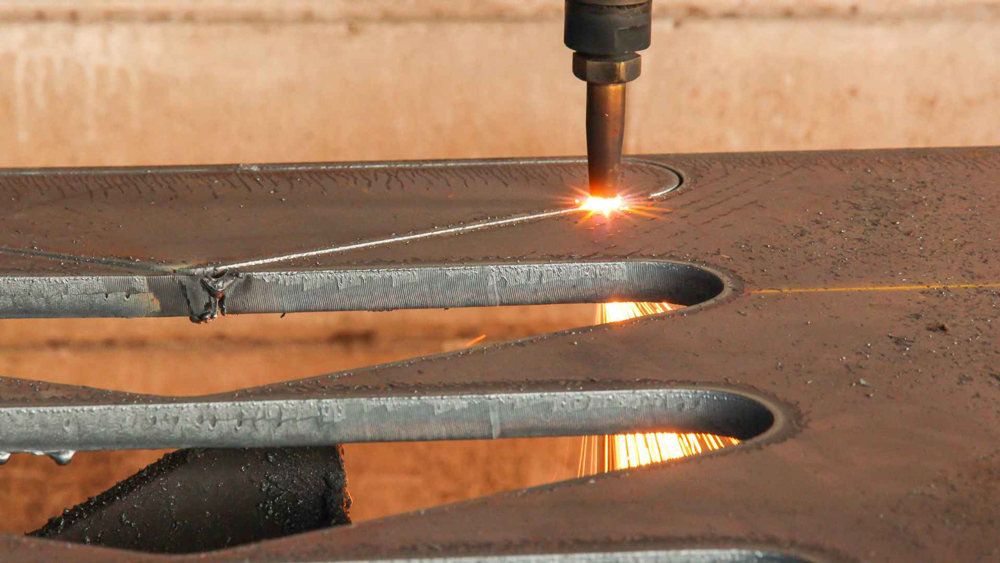

Cut edge cracking is likely to occur when thermal cutting methods (flame cutting, plasma cutting, and laser cutting) are used, the crack will be visible from 48 hours up to several weeks, for this reason, cut edge cracking is also defined as delayed cracking. Cut edge cracking is mainly influenced by two effects:

hydrogen content

residual stresses in the steel plate

Tip 1: Pre-Heat the Plate before Cutting

The most common method to avoid cut-edge cracking is pre-heat the steel plate to a certain temperature, and cut it while the material is still warm.

Tip 2: Slow Down Your Cutting Speed during Cutting

The residual stress will be reduced by slowing down the cutting speed. Because while cutting speed is reduced, the material heats up around the cut front, and the heat-affected zone will be wider. But you should remember one thing: slow down the cutting speed is not as reliable as pre-heating.

Tip 3: Post-Heat or Slow Cooling the Plate after Cutting

Post-heating is one of the most effective ways to avoid cut-edge cracking. It should be done immediately after the cutting process is finished, heating up the temperature and remaining for a few hours in a furnace or with torches, but be attention: Do not overheat!

Regardless of whether or not you used the method of pre-heating, an appropriate slow cooling rate is an approachable way to reduce the risk of cracking.

Due to the cracking in the weld metal or heat-affected zone of the wear-resistant plate, the welding of the wear-resistant plate is a kind of challenge. The following factors constitute the principal causes of this type of cracking:

The cooling speed

high hydrogen in the weld metal

filler metal

Tip 1: Keep Your Welding Surface Clean

Keep the joint clear from impurities like rust, grease, oil, or frost to avoid hydrogen cracking.

Tip 2: Pre-Heating & Slow Cooling

Just like cutting the wear-resistant plate, preheating and slow cooling is a kind of efficient way to reduce HAZ (heat-affected zone), which could widely prevent cracking.

Tip 3: Appropriate Filling Metal

Filler metal selection should be based on the tensile strength of the base metal to which the plate will be welded. A filler metal with the least amount of hydrogen content and the lowest tensile strength that still provides a high enough impact value can help welding operators combat the potential for cracking.

Compared to other materials, the bending of the wear-resistant plate is more difficult to master, which is mainly due to its high strength and poor elasticity.

Tip 1: Bend the Sheet beyond the Desired Angle

Compared with carbon steel, the wear-resistant plate has a low elongation rate, and the bending angle R of the workpiece during bending is larger than that of carbon steel, otherwise, there may cause cracking.

Tip 2: Accounting for Bend Allowance

It is vital in knowing how to bend sheet metal. It would guarantee more error-free numbers ensuring perfection in finished products.

Tip 3: Always Use a Press Brake

It's your guarantee to get a smooth and surface-clean product.

Editor's Note

If you're using wear-resistant steels, high strength steels, or other thick steel materials with high carbon equivalent for your business, taking the right measures to prevent cracking can be a huge cost reduction.

Do remember to check the processing guide of your own plate brand! Due to the characteristic of the wear-resistant plate, every mill has its own stand of processing, such as the pre-heat temperature, cutting speed, filling metal, etc., Following the suggestions of the guide can mostly prevent you from cracking!

CUMIC Steel Limited, led by an internationally experienced team of industry experts, is specialized in trading wear-resistant steel plate for over a decade. Our team of sales engineers, technicians and consultants are ready to work with you to select the most suitable steel and employ the most efficient manufacturing processes. Get a tailored supply solution today by emailing us at cumic@cumic.com