When you picture the oil & gas industry, you might see offshore rigs, miles of pipelines, and massive storage tanks. But behind all of that infrastructure lies one critical material: steel. From drilling deep wells, to transporting crude across continents, to refining the final product—steel is the backbone that keeps the energy world running.

1. Material Insights: Selecting High-Performance Steel

1.1 Offshore Platforms & FPSOs for Harsh Marine Conditions

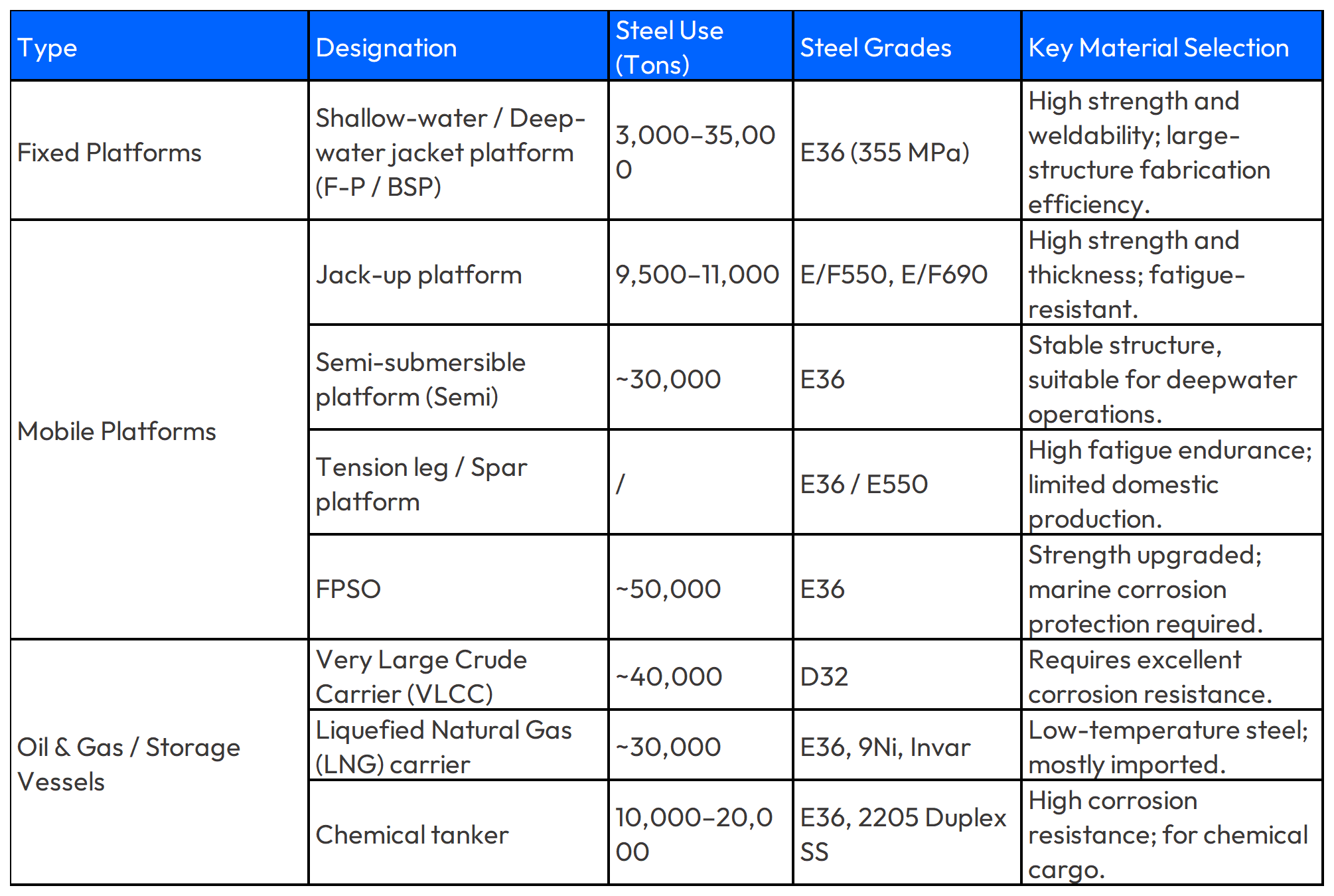

In the ocean, everything works against you: salt spray, waves, shifting loads. Steel here must be strong enough to hold massive structures, weldable enough to build large-modules, and durable enough to resist decades of fatigue and corrosion. Using the wrong grade isn’t just costly—it can be unsafe. Below is a representative selection of platform & vessel types, steel tonnages, grades and the key material-criteria to keep in mind.

Steel material selection for offshore platforms

1.2 Pipeline Applications

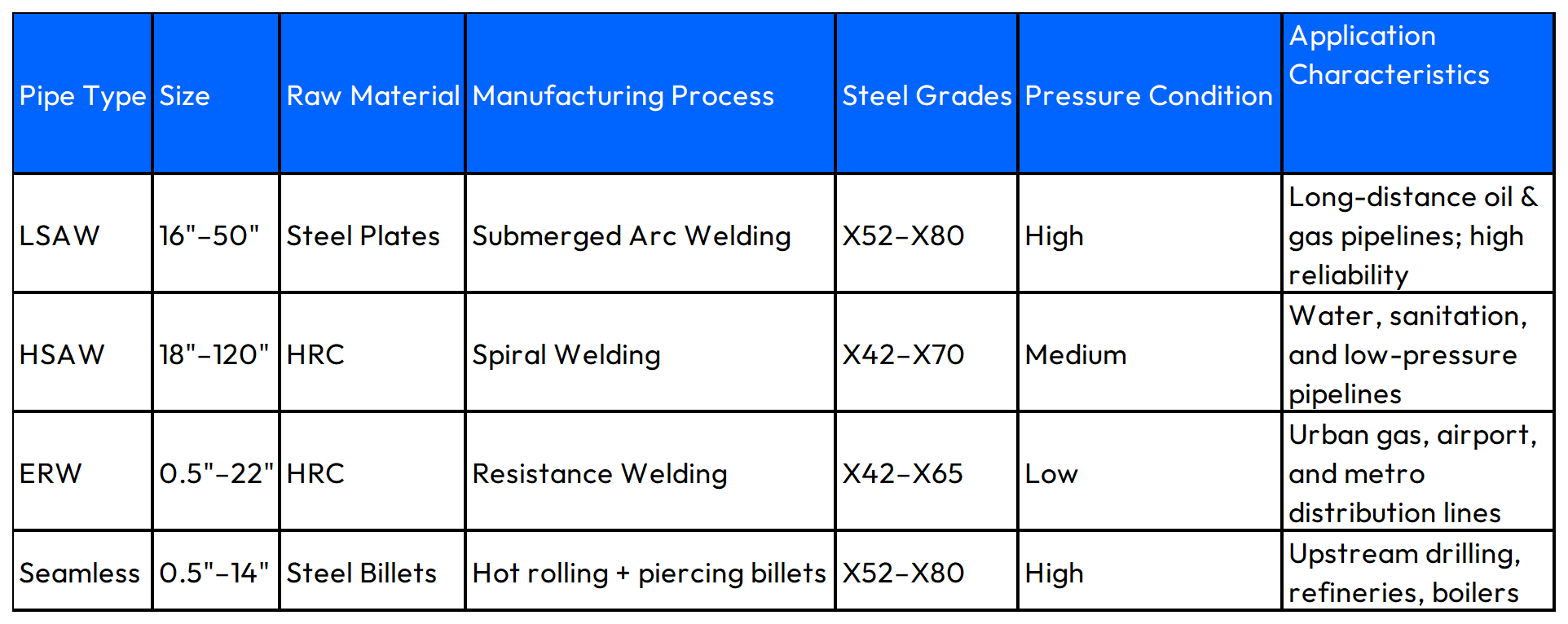

Whether carrying oil, gas, or liquids, pipelines are stretched across harsh terrain and pressed into service under extreme pressure. From seamless pipes handling upstream wells to large-diameter line pipes in midstream applications, the material must match the job. Job specs vary: pipe size, pressure, transported medium, environment—all influence steel selection.

Steel selection for Oil & Gas pipelines

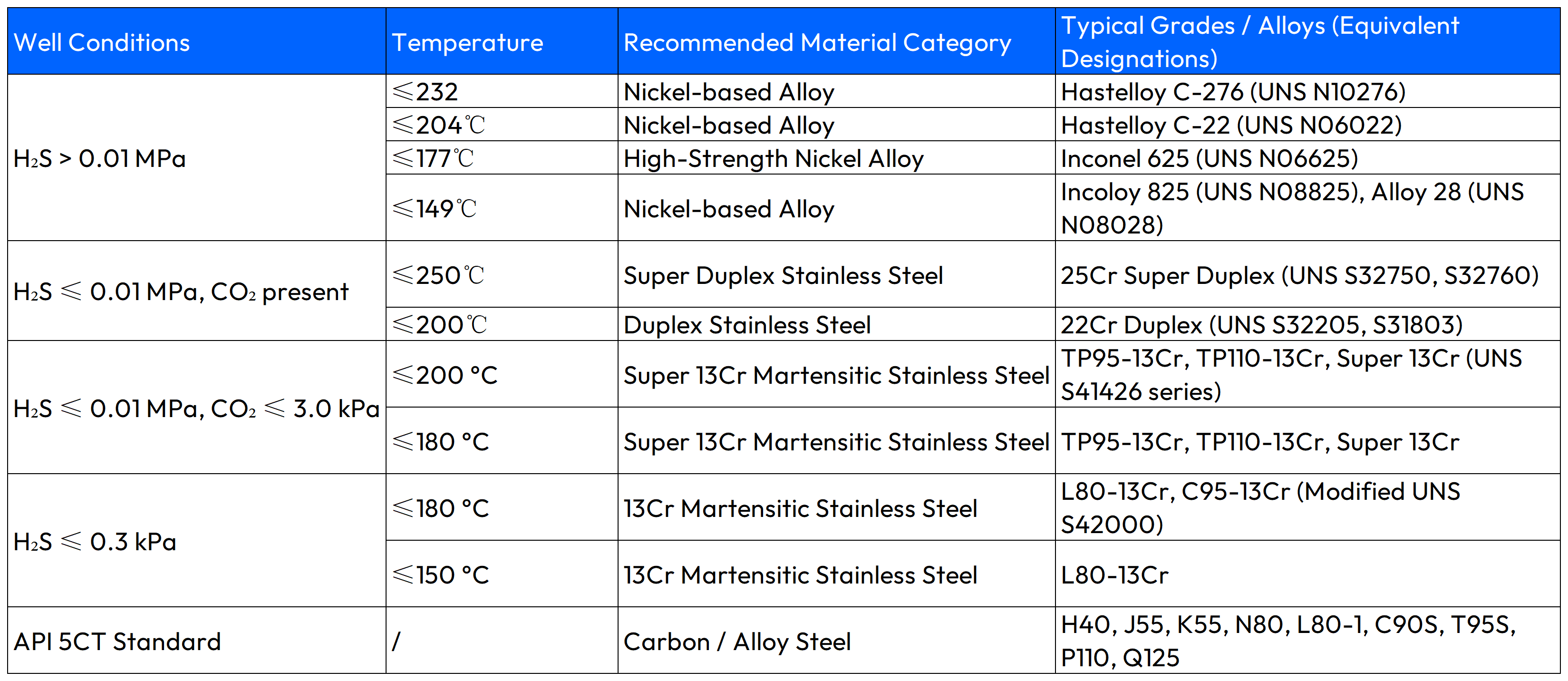

1.3 Oil Country Tubular Goods (OCTG) for Complex Well Conditions

Well-casing, tubing and drill-pipes face some of the toughest conditions in the oil & gas sequence: high pressure, high temperature, sour service (H₂S / CO₂), hydrogen embrittlement, fatigue, and corrosive formation fluids. Material selection in OCTG must strike a balance between strength, toughness, corrosion resistance and service life. Many OCTG applications conform to API Spec 5CT; more extreme sour-service wells may require API Spec 5CRA certified materials.

Steel selection for OCTG

2. How Steel Suppliers and Project Stakeholders Can Work Together

Given the complexity of modern oil & gas projects and the demanding environments, collaboration between steel suppliers, fabricators, EPCs and end-users is critical. Here are some best-practice pointers:

Early engagement – Suppliers should be brought in during front-end engineering design (FEED) so that steel grade selection, procurement lead-times, fabricator compatibility and logistics are factored.

Technical advisory – Offer technical consultations on grade choice, corrosion modelling, fatty fatigue assessment, weldability and fabrication strategy.

Documentation & quality control – Full Mill Test Reports (MTRs), non-destructive testing records, welding procedures, certification to API/NACE/ISO.

Lifecycle orientation – Move beyond “just supply” to “lifecycle partner” mindset: help the client with inspection strategies, future upgrades (e.g., for hydrogen transport), and pre-emptive maintenance.

Sustainability considerations – With the energy transition underway, clients increasingly care about sustainability credentials of steel (recycled content, decarbonised production, circular economy). This positioning becomes a differentiator.

If You’d Like to Explore Further…

If you’re planning an oil & gas project —whether upstream, midstream or downstream — and want integrated services like navigating steel grade selection, fabrication logistics or supplier options, we’d be happy to talk. At CUMIC, we have decades of experience delivering steel solutions to demanding energy applications globally. Contact us for a consultation.