In our previous article, we explored the roles of low-carbon steel and galvanized steel in automotive manufacturing, focusing on their formability, cost-effectiveness, and corrosion resistance that make them indispensable for body panels, fuel tanks, and structural components.

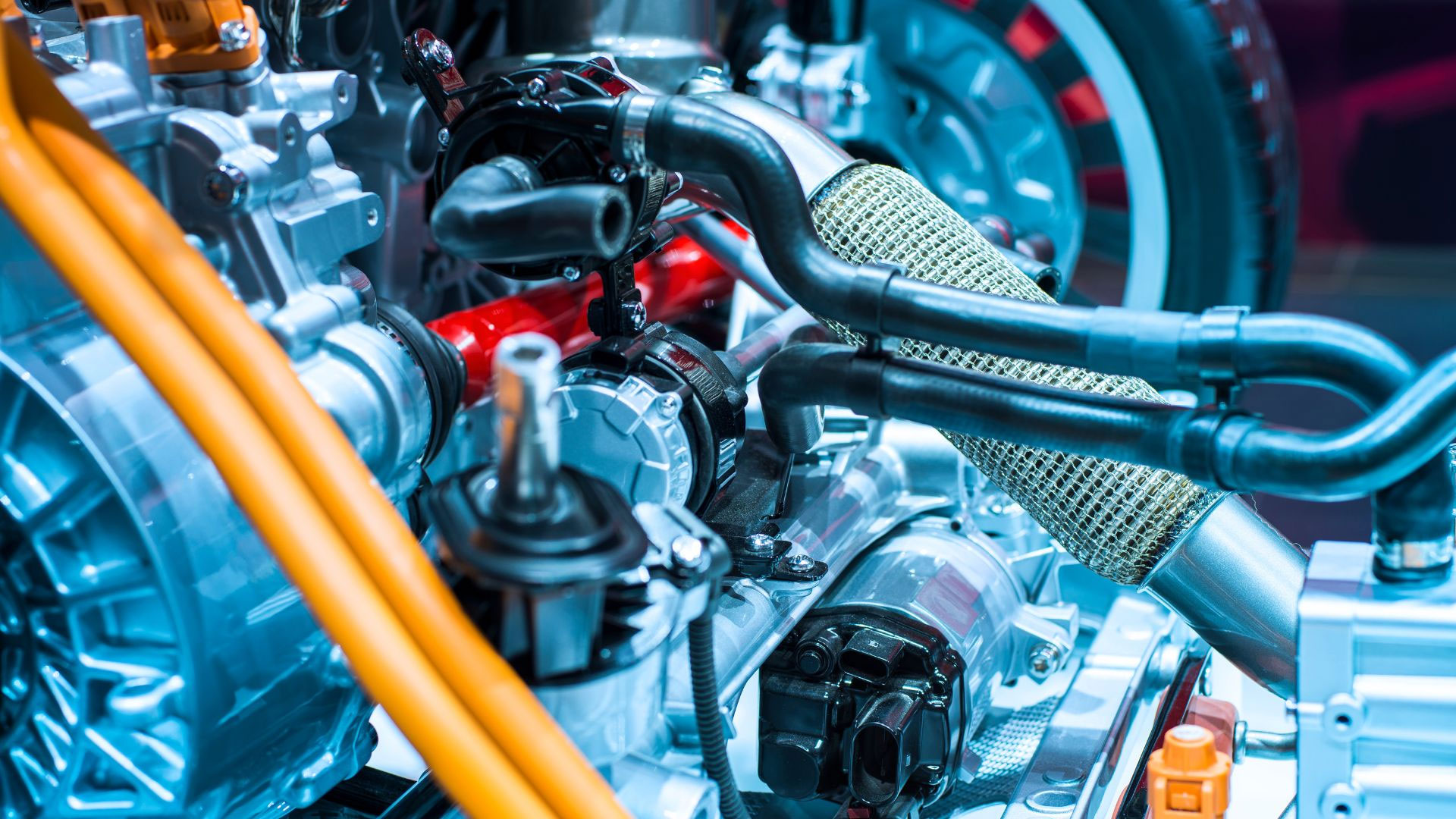

In this continuation, we turn our attention to the next group of steels essential to modern automotive engineering: high-carbon steel, stainless steel, galvanized steel, and advanced high-strength steel (AHSS). These materials bring unique advantages in terms of strength, durability, corrosion resistance, and safety—helping automakers meet the evolving demands of performance, sustainability, and crash protection.

High-carbon steel contains 0.6%–1.0% carbon, making it significantly harder and more brittle than low-carbon steel. It is renowned for its exceptional hardness, wear resistance, and ability to withstand extreme stress.

Key Properties:

High Strength & Hardness: Resists deformation under heavy loads.

Superior Wear Resistance: Ideal for components exposed to friction and repeated impact.

Lower Ductility: Less flexible, not suitable for large body panels.

Applications in Automotive:

Suspension springs.

Transmission components.

High-stress structural parts requiring rigidity and durability.

Stainless steel contains a minimum of 10.5% chromium, which forms a protective oxide layer that resists rust and oxidation. It is widely used in vehicles for both functional and decorative purposes.

Key Properties:

Excellent Corrosion Resistance: Withstands exposure to water, road salt, and harsh weather.

High Durability: Maintains performance under heat and mechanical stress.

Premium Finish: Offers polished, attractive surfaces for visible components.

Applications in Automotive:

Exhaust systems.

Heat shields and fuel lines.

Decorative trims and fasteners.

AHSS represents a major advancement in automotive steel technology, combining high strength with reduced weight. Manufactured through specialized alloying and heat-treatment processes, AHSS helps automakers achieve both safety and fuel efficiency goals.

Key Properties:

High Strength-to-Weight Ratio: Provides crash protection without adding excess weight.

Superior Energy Absorption: Distributes crash forces effectively for passenger safety.

Fuel Efficiency Contribution: Enables lighter vehicle designs that meet emission standards.

Applications in Automotive:

Safety cages.

Impact beams.

Structural reinforcements.

At CUMIC, we partner with leading mills worldwide to deliver carbon, galvanized, AHSS, and special automotive steel tailored to your automotive design and performance needs. With integrated service including global sourcing network, seamless logistics, expert metallurgical support and more, we ensure your steel meets specifications, delivery timelines, and quality benchmarks.